Cost? (An Electric Motor Price Guide)

Looking for a suitable electric motor but not sure about the estimated cost? Quoting the exact price of an electric motor without specified information is overwhelming.

The electric motor cost breakdown significantly depends on various factors such as region, type, specifications, and much more.

Figure 1: Different electric motor prices

Finding affordable yet high-quality motors is unquestionably exhausting. However, you must understand the factors that impact the pricing of an electric motor before purchasing.

But how do I find the best electric motor cost?

Don’t worry! We got you covered.

We have bent over backward to help you to find affordable, reliable, and standard-quality electric motors. This pricing guide will give you enough knowledge to discover the best pricing for electric motors.

So, without any further due, let’s find out!

Different types of electric motors costs:

Figure 2: Common types of electric motors

It is practically impossible to provide an accurate electric motor cost because motors are specified according to their functions, specifications, and applications.

Moreover, the pricing of electric motors also depends on their size, output rating, RPM, and other factors.

Here is the list of some most commonly used electric motors and their price ranges;

1. Three-phase motors

Three phase motors are widely used electric motors in the industry. These motors are quite expensive due to their construction complexity and wide range of applications.

The average cost of 3-phase motors ranges from $100 to $500.

Does the price of a three-phase motor vary?

Yes, since the price range depends on the frame size, power rating, and construction material, it varies.

2. Single phase motors

Single-phase electric motors are usually rated at 220V and 50 HZ frequency. These motors are ideal for domestic settings.

Although single-phase motors can cost a few dollars, some single phase motors, such as induction motors could cost up to a thousand dollars.

The average single phase electric motor price falls between $25 to $300.

Relevant Read: Understanding Single Phase Electric Motor Prices

3. Explosion-proof electric motors

Figure 3: Explosion-proof motors

Explosion-proof motors are specialized motors designed for hazardous locations to protect motors from ignition material and fire. Since these motors have extended duty life and protection, they are a bit on the expensive side.

The price of these motors depends on protection class/division, insulation type, horsepower rating, and other features.

However, the cost of explosion-proof motors ranges from $500 to $1500 on average.

Related Guide: Explosion-Proof AC Motor

4. Industrial motors

Industrial motors are ideal for high-grade commercial applications because they feature high voltage ratings, rpm (revolution per minute), output hp, and operational power.

Typically, industrial motors cost somewhere between $500 to $2000.

Which factors affect the electric motor cost?

Now, you must wonder what makes an electric motor expensive or cheaper.

Right?

Although manufacturers keep several factors in mind while calculating the price of an electric motor.

Let’s dive deep into some common factors that influence the pricing of an electric motor;

Voltage and Power output:

Motors designed to tolerate higher voltages tend to be more expensive than compact domestic motors with lower voltage rating.

For example, Industrial grade motors with larger frame sizes are priced higher than low-grade motors. Similarly, 7-horsepower (rated output power) motors are costlier than 1 hp electric motors.

Specifications:

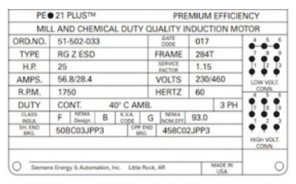

Figure 4: Electric motor specifications

You must understand that motor specifications such as rpm, efficiency, construction type, and special features directly affect the price of motors.

Explosion-proof motors cost more than simple construction motors with the same voltage and horsepower rating because they have special features.

Other considerable features of electric motors that impact pricing include; lifespan, ambient temperature, IP rating, water resistance, and duty type.

Raw material:

Remember! The manufacturing material of an electric motor is a mirror of its quality.

Therefore, electric motor costs fairly depend on the quality of raw materials used in the production.

For instance, electric motors manufactured with 100% stainless steel, copper coil, and thick aluminum are expected to be priced higher than motors with low-quality manufacturing material.

Pro Tip #1: Always investigate the raw material of the motor before buying it to better estimate the price range.

Shipping cost:

Electric motor cost also depends on the shipping and logistic cost. Shipping costs can be determined by location, shipment type, and weight/ measurement.

#Things to Avoid: Avoid choosing international manufacturers without reliable logistic services. You may end up paying way more than local sellers due to the high shipping cost.

3 Tips to find the best pricing of the electric motor (Best recommendation):

Then how to buy a desired one at budget-friendly rates?

Now, that’s an appropriate question.

Here are some quick tips you can follow to buy your desired motor at the best price.

1. Explore the Market: Don’t choose a manufacturer blindly. Explore the market, and evaluate the quality, services, and pricing of different suppliers to bag the right deal for you.

2. Prefer Bulk Orders: Bulk orders add discounts and room for negotiation. If you are looking for an electric motor for commercial purposes, go for large numbers at once to get lower rates.

3. Look for Low Shipping Costs: Consider suppliers that offer reliable yet cost-effective shipping. Calculate the motor cost and shipping cost to choose a suitable option.

MINGGE Motor–China’s top-rated electric motor manufacturer

MINGGE Motor is China’s leading electric motor manufacturer and global supplier. MINGGE designs a wide range of electric motors, including three-phase, permanent magnet, and industrial motors.

We have over 20+ years of experience manufacturing highly operational and durable electric motors. MINGGE has a high production capacity with capable engineers and QC (quality control) teams.

MINGGE features advanced equipment and premium raw material to craft top-notch electric motors. Furthermore, we provide our customers with 100% customization for voltage, frequency, terminal box, and output speed.

So, what are you looking for? Contact us for a free quote and more information. Our customer care is available around the clock to assist you.

FAQs:

1. Why do electric motors fail?

Electric motors fail or burn out caused by several reasons; however, the most common factors that cause electric motor failure is overheating and insulation breakdown.

2. Are electric motors without copper affordable?

Copper as a manufacturing material in electric motors ensures error-free functioning for an extended period. Electric motors without pure copper are less pricey, but such motors have low working quality and duty life.

Post time: Apr-15-2023